Extreme microscopy helps materials reach market

Novel materials often lead to new products, but taking a material to market can require an atomic-level understanding of its properties. In 2016, three Danish universities established LINX: A service for companies who need to understand materials. Med-tech silicone specialists BioModics was one of the first companies to sign up. They collaborated with a Copenhagen Science City-based partner. By Jes Andersen.

Access to expert analytical methods

BioModics is seeking approval for a medical device based on a newly invented silicone material. LINX provides a one-stop-shop to analytical methods covering length scales ranging from very small to even smaller. Here, BioModics could access advanced neutron- and X-ray-facilities and researchers who are experts in their use, BioModics CEO Peter Thomsen explains.

These are expert analytical methods that require specialist training. We did not have the skills and experience in-house to run such analysis and to process and interpret the analytical data. That is why we teamed up with leading experts in the field”: Peter Thomsen, CEO, BioModics.

Fiendishly difficult to analyse

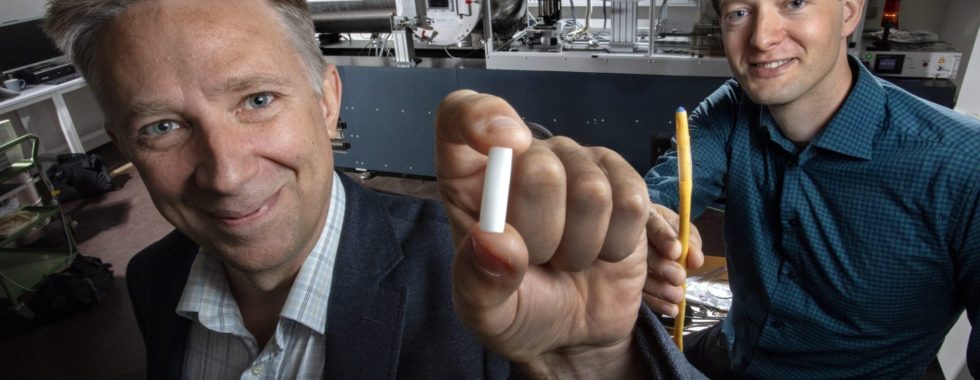

Through LINX, BioModics found the physicist Erik Brok from Copenhagen Science City-partner University of Copenhagen’s Niels Bohr Institute. The company’s most recent invention is a complex interlacing of silicone rubber and hydrogel named IPN. The mixed material shows promise as a reservoir for medicine that needs to be released continuously. The mix makes it fiendishly difficult to analyse though, says Brok.

“Materials used in real-world applications are far from the idealised materials we study in academia. We were able to apply our methods and data analysis directly to studying BioModics IPN-material, but the complicated structure has led us to combine more of the techniques available in our toolbox than is usually the case”, says Erik Brok.

Microscope with 3D add-on

Neutron and X-ray facilities are a bit like microscopes. They give an enlarged picture, but they also provide three-dimensional information. 3D information was crucial to understanding BioModics drug delivery material, because its morphology, its dimensions and structure, determines how fast it will release the medicine.

Crucial collaboration in an atmosphere of trust

Understanding the release profile goes from crucial to vital, when the company applies for permission to market the material as a medical device. Despite the business critical nature of the work, Peter Thomsen has felt very trustful towards the university during the process.

We have established an open innovation platform, where we work really close together, share knowhow and ideas and have no secrets. This is built on trust and a shared purpose. I was surprised at how easy it was to establish such a platform”, says Peter Thomsen.

Benefits for company and researcher alike

The IPN material will be a so-called implantable medical device. BioModics and Brok still has to prove some of its properties in order to earn a CE marking, but the physicist is confident that the collaboration holds benefits for him as well as for the company.

“I look very much forward to combining all the results into a good story, where parts that are not sensitive can be shared with the research community and other parts can be useful for BioModics in their development and production”, says Erik Brok.

Small-scale validation of large-scale collaboration

For this project, Brok used apparatus at University of Copenhagen in combination with Neutron facilities in Munich, Delft and Grenoble. Starting in 2023, LINX will open the door to one of the most powerful facilities in the world, when ESS, the European Spallation Source in Lund, Sweden, comes online. Jimmy Binderup Andersen, who is CEO of Copenhagen Science City-based LINX is delighted that the company and the researcher both benefitted from the collaboration.

Highly skilled scientists in combination with state-of-the-art research infrastructure presents a unique value to our industrial partners. Innovative and collaboratively minded university researchers will help Danish industry achieve a position of excellence in material science. I sincerely believe that society, as a whole, will benefit from this type of co-creation”, says Jimmy Binderup Andersen, CEO, LINX.